Advanced CNC Machines of

PMC-Colinet™

- Home

- Machines

Precision-Engineered Machines Tailored for Your Specific Applications

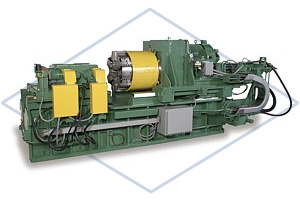

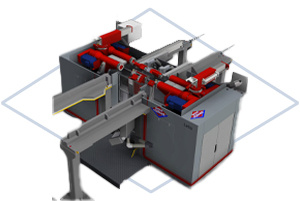

PMC-Colinet, a Park Ohio company, creates high-performance, customized pipe threading and coupling machines built for OCTG and other industrial manufacturing applications. Backed by our experienced team, we get you efficient, productive machines that are proven to last.

Let’s Build Your Custom Solution

Speak with our team to see how PMC-Colinet’s machines and dedicated support can increase the output, efficiency and quality of your production line.